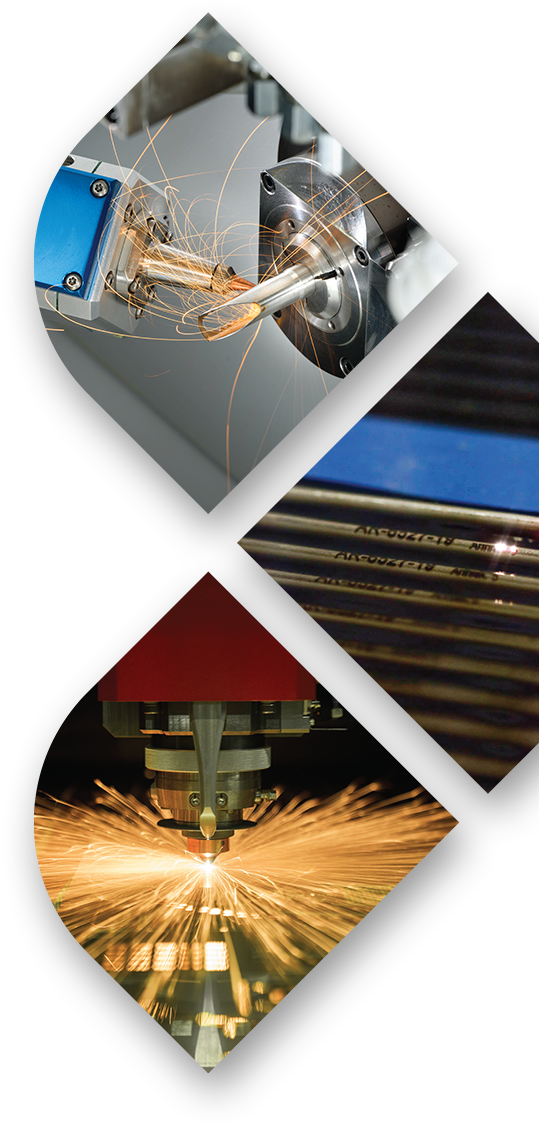

Precision Laser Processing

Innovative Laser Processing Technologies for Medical Devices

We offer:

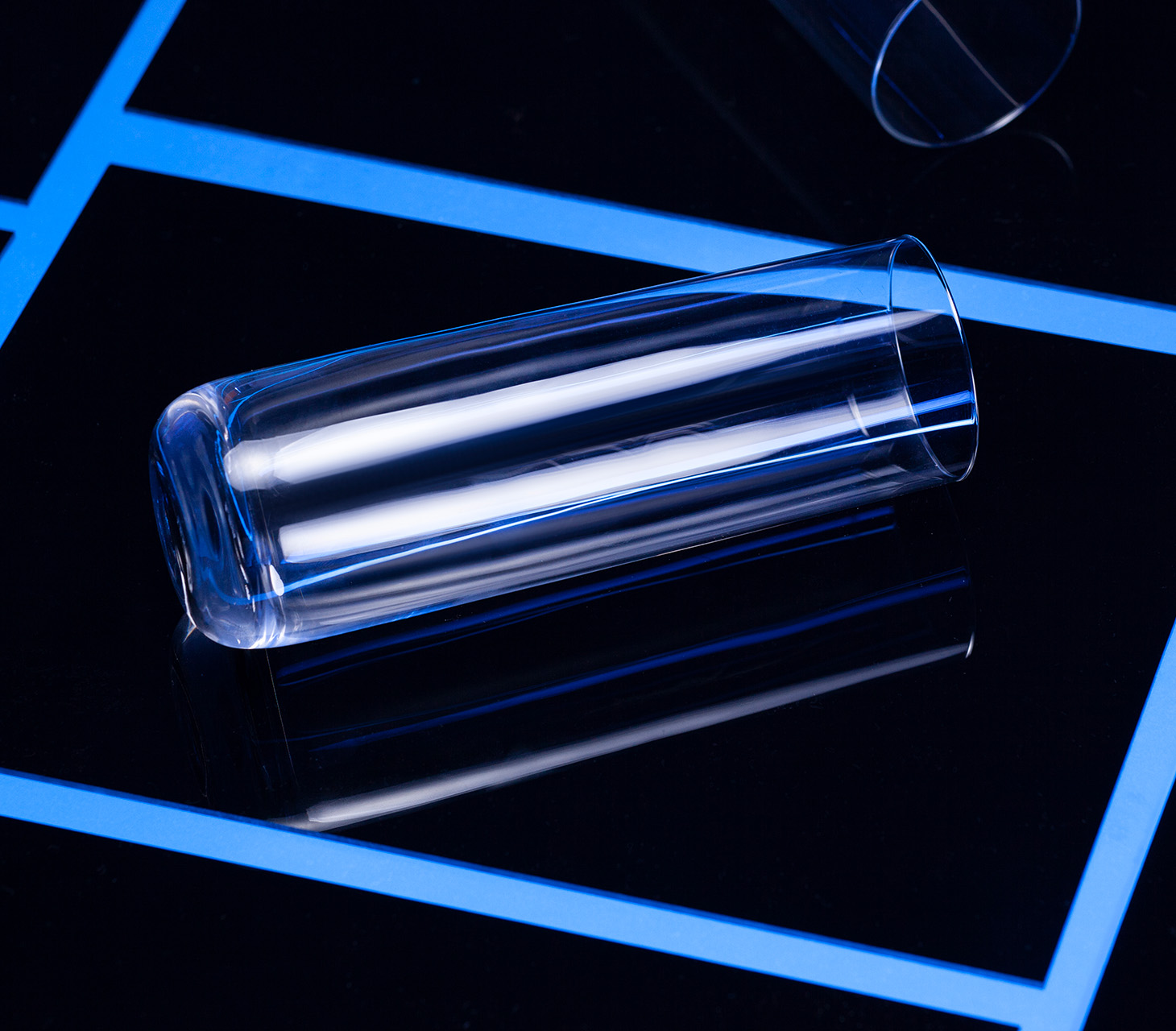

Laser Ablation

Our laser ablation process utilizes controlled laser pulses to precisely remove material from substrates, minimizing thermal distortion. Benefits include:

- High Precision: Nanometer-scale tolerances.

- Fine Surface Finishes: Virtually burr-free results.

- 3D Ablation of PEEK: Ideal for implants.

- Microfluidic Channels: Precision machining capabilities.

- Coating Removal: Efficiently removes polyimide or parylene from catheters and guidewires.

Laser Cutting

Laser cutting at Cadence is customized for surgical devices, ensuring:

- High-Speed and Flexibility: Adaptable to various materials including metals and plastics.

- Precision: 4-axis and 6-axis cutting for complex components.

- Cost-Effectiveness: Reduces tooling expenses with no consumable costs.

Laser Drilling

Our laser drilling process excels in creating small holes with large depth-to-diameter ratios. Key advantages include:

- Micron-Level Tolerances: Non-contact material removal.

- High Efficiency: Rapid hole creation, down to 5 microns in size.

- Dynamic Customization: Adjustable hole dimensions and shapes.

Laser Marking

Laser marking provides high precision and repeatability, perfect for medical applications. Features include:

- Customized Solutions: Tailored marking for various components and devices.

- Integrated Processes: Compatible with cutting and welding, enhancing efficiency.

Laser Tube Cutting

Cadence's laser tube cutting technology ensures:

- Rapid Production: High precision for medical instruments like stents.

- Complex Geometries: Accurate cuts on diverse tubing materials.

- Automation: Streamlined processes with no downtime.

Laser Welding

We deliver high-quality laser welding solutions with advantages such as:

- Consistent Joints: Minimal heat-affected zones and high repeatability.

- Advanced Techniques: Micro-weld and dual-beam technologies for complex parts.

LaserSwiss Machining

Our LaserSwiss machining integrates 6-axis Swiss machining with laser cutting and welding, offering:

- Enhanced Productivity: Reduces setup time and operational complexity.

- High Precision: Achieves superior results in seconds.

Cadence’s innovative laser processing technologies provide superior precision and efficiency, meeting the rigorous demands of the medical device industry. These vertically integrated capabilities help streamline Cadence’s manufacturing processes, supporting the advancement of medical and surgical devices worldwide.

Contact Cadence for your precision laser processing needs.

How Can We Help You?

"*" indicates required fields

* indicates required fields