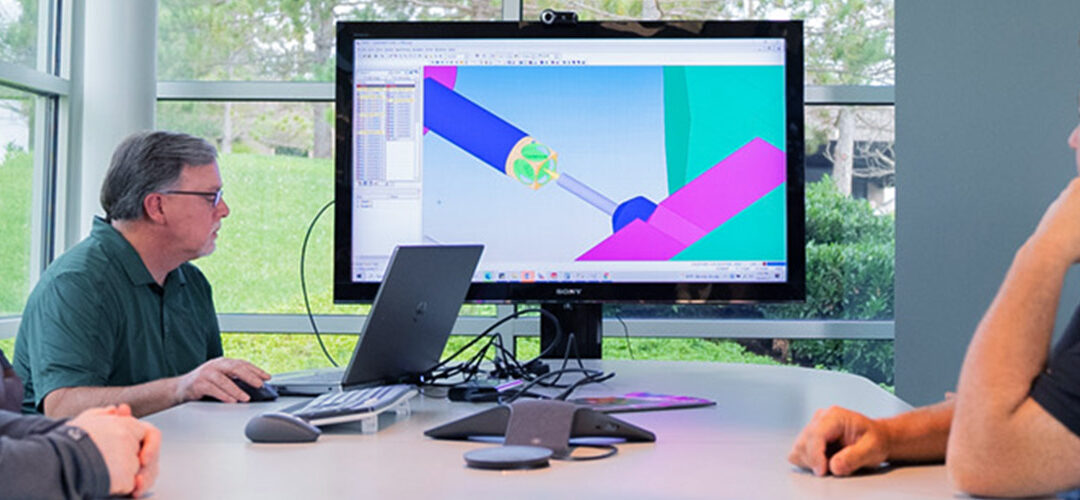

In the highly regulated and complex field of medical device manufacturing, having a partner who can provide comprehensive, end-to-end solutions is invaluable. At Cadence, we offer a complete suite of services that span the entire lifecycle of a medical device, from initial design and development to final assembly and after-market support. Our seamless integration of each phase ensures that we deliver high-quality, reliable products that meet the rigorous standards of the medical industry. Product Design and Development The journey of a medical device begins with a concept. At Cadence, our experienced teams work closely with clients to bring their ideas to life. We utilize advanced computer-aided design (CAD) software and simulation tools to create detailed models and prototypes. Our collaborative approach ensures that all aspects of the device, from functionality to manufacturability, are thoroughly considered. During the design phase, we focus on innovation and precision. Our engineers leverage their extensive knowledge of materials and processes to optimize the design for performance and cost-effectiveness. We also conduct rigorous testing and validation to ensure that the...