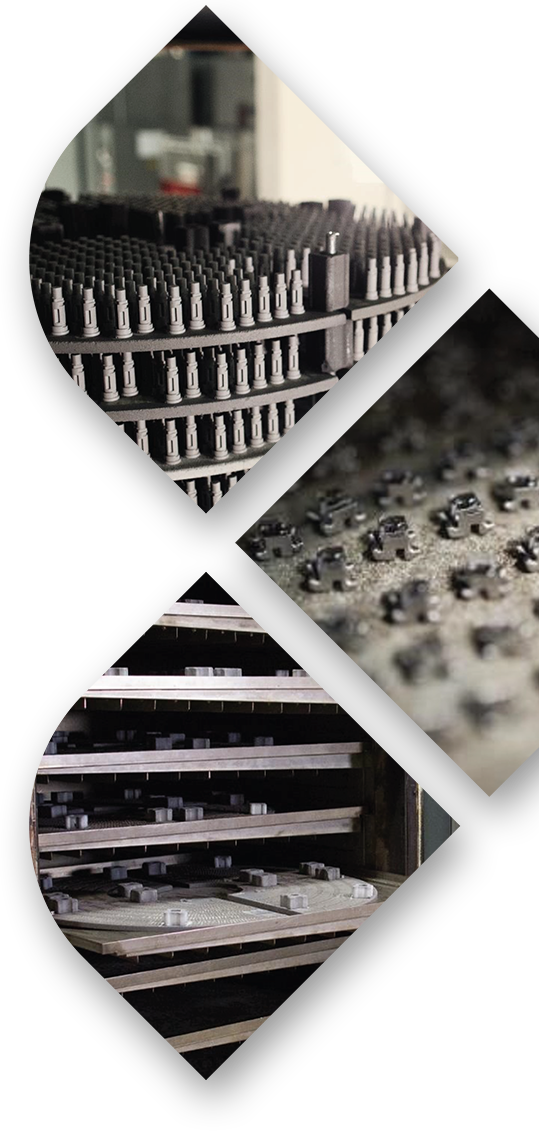

Metal Injection Molding

Complex MIM Parts for Various Surgical Applications

We are a leading contract manufacturer, providing complex MIM parts for various surgical applications, as well as:

- Energy-based device components and sub-assemblies

- Overmolding, potting, and electrical testing

- Full suite of secondary operations (machining, EDM, heat treating, etc.)

The medical community requires smaller components for minimally invasive procedures. This means tighter tolerances, thinner walls, and more precise features that are possible with MIM. The MIM capability also helps medical device OEMs with cost savings projects that reduce part count, improves mechanical properties, and reduces the cost of items that require recurring replacement or maintenance.

Medical MIM Expertise:

- Micro MIM

- Complex geometries

- Thin wall capabilities

- Customizable feedstock

- Wide range of alloys

- Electrical and mechanical assembly

- Debind versatility

- Precision tooling

- And much more!

Cadence enables its OEM customers to efficiently scale production while maintaining cost-effectiveness. The MIM capability not only enhances our customers’ production capacity but also supports their commitment to innovation in the MedTech industry.

Contact us today to learn more about our complex MIM parts for medical devices.

How Can We Help You?

"*" indicates required fields

* indicates required fields